bauxite processing in netherlands

مجال التطبيق

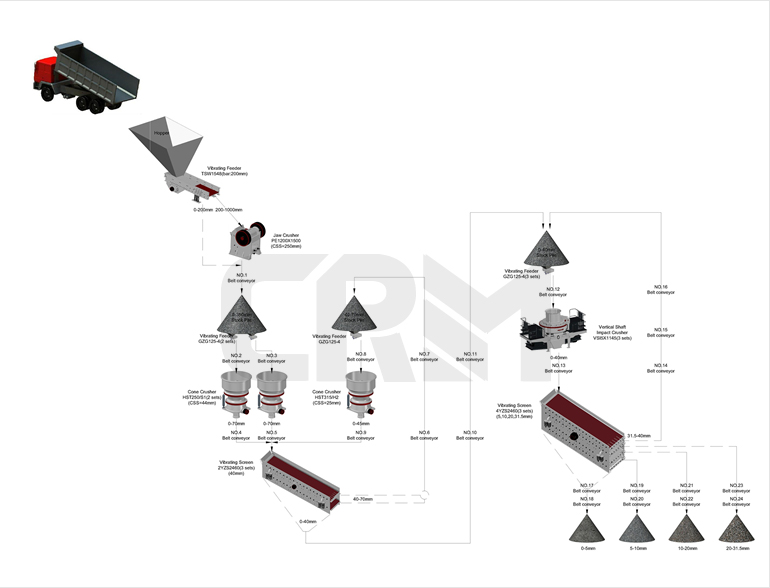

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

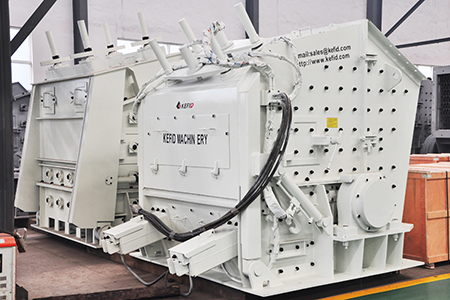

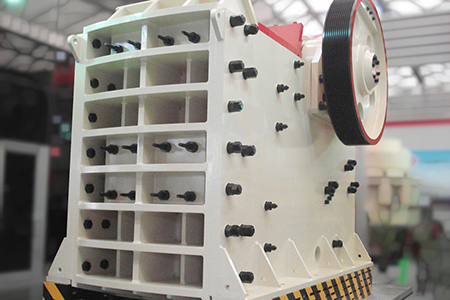

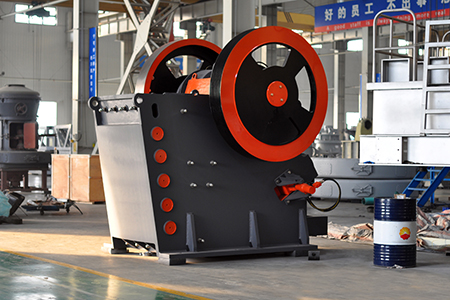

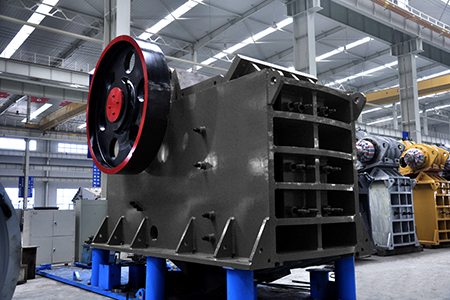

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals ...

2022年1月23日 This Chapter provides an introduction to the Bayer process and how the mineral composition of bauxites affects the process variants and the principal parameters to be selected.

The processing of high silica bauxites - ScienceDirect

2009年8月1日 This document will critically review existing and potential processes for the processing of high silica bauxites. High silica bauxites are usually considered to be those with

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed

Chemical Processing of Bauxite: Alumina and Silica

This Chapter provides an introduction to the Bayer process and how the mineral composition of bauxites affects the process variants and the principal parameters to be selected. The

Mapping the research landscape of bauxite by-products (red

2024年2月15日 Geographical and production challenges surround bauxite, presenting geo-economic and environmental challenges. A critical concern in aluminium production is

Increasing Resource Efficiency of Bauxites Using LIBS

Our results showed that LIBS is a very promising technology to define the bottom and top layer of bauxite ores and to access critical parameters crucial for bauxite mining and processing. First LIBS tests were made on scandium standards

Technology strategies for sustainable metals production systems:

2006年1月1日 Bauxite is processed into pure aluminium oxide (Al 2 O 3), so-called alumina, before it can be converted into primary aluminium by electrolysis. This is achieved through the

Bauxite Processing Plant - CFlo

Our equipment is introduced at the clarification and classification stage of bauxite processing. Each hydrocyclone configuration is designed to meet the specific requirements of your mining

Bauxite: Geology, Mineralogy, Resources, Reserves and Beneficiation

In this chapter the Authors summarize the typical features of bauxite which are believed to play roles in mining, beneficiation and mainly in alumina processing, that is, the industrial value of

The processing of high silica bauxites - ScienceDirect

2009年8月1日 1. Introduction1.1.. ScopeThis document will critically review existing and potential processes for the processing of high silica bauxites. High silica bauxites are usually considered to be those with reactive silica contents in excess of ∼. 8% by weight of the bauxite (reactive silica is defined later in this paper).. This review is limited to bauxites as feedstocks

Bayer process - Wikipedia

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer.Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al 2 O 3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. [1] The aluminium oxide must be further purified

Bauxite Deposits in Suriname: Geological Context and

In 1941, the The bauxite deposits in South America are situated in four SBM opened the Paranam bauxite processing plant, named af- subprovinces of the Amazon Platform. The Guiana Shield sub- ter the Para and Suriname Rivers

The Bauxite Industry and Its Development SpringerLink

2023年10月25日 The metal aluminium was first discovered and named by British scientist, Sir Humphrey Davy, in 1808. French chemist, Pierre Berthier while working near Les Baux in southern France in 1821, discovered soil with high quantities of aluminium oxide (or alumina) and named it bauxite after the village (Davis 1989; Gow and Lozej 1993).The material was

Evaluating the Behavior of Bauxite Tailings Dewatering in

2023年9月6日 Depending on the ore quality, a washing process can be conducted with the bauxite, which basically consists of scrubbing the ore and screening in order to increase the available alumina grade, i.e., the alumina extractable using the Bayer Process, and reduce the impurity content. Tailings are usually disposed of in a tailings dam in the form of a slurry, which

Petrological Characteristics of Lateritic Bauxite Deposits of India

Petrological Characteristics of Lateritic Bauxite Deposits of India and Their Significance in Mineral Processing Pravin Bhukte*, Gopal Daware, Tejas Bhosale, Bhargavi Kulkarni and Anupam Agnihotri Jawaharlal Nehru Aluminium Research Development and Design Centre (JNARDDC), Amravati Road, Wadi, Nagpur-440 023 (MS), India

Environmental impacts of extraction and processing of raw

2024年2月8日 The following metals are assessed: iron (steel), bauxite (aluminium), copper, silicon, graphite, zinc, nickel, chromium, manganese, lithium, cobalt, molybdenum and rare earth elements (REEs). The report looks beyond the EU’s critical raw material list, and includes chromium, molybdenum, zinc, and steel, since these are important for the energy transition

The Chemistry and Processing of Jamaican Bauxite

2014年6月13日 References. see for example, R.J. Lancashire, "Bauxite and aluminium production", Education in Chemistry, May 1982, pps 62-64. Production figures on Bauxite from Victoria in Australia are available at the National Resources and Environment website under 'Minerals and Petroleum'. A preview of the book on the Global Bauxite Industry For the latest

Plant phosphorus availability index in rehabilitated bauxite-processing

Background and aimsSoil phosphorus (P) indices that have been originally developed and applied to agricultural soils for predicting P uptake by plants were examined in a pot experiment to determine the most suitable index for P availability in bauxite-processing residue sand (BRS).MethodsPot trials with ryegrass were established using BRS that had been amended

Bauxite in Indonesia - Mining Technology

2024年8月23日 Indonesia accounts for 5% of global production, with the largest producers being the Republic of Guinea, Australia, China and Brazil. Exports of bauxite from Indonesia increased by 2% in 2023 over 2022. Indonesia’s bauxite exports are expected to grow at a CAGR of 0.98% between 2023 and 2027.

Petrological Characteristics of Lateritic Bauxite Deposits of India

Petrological Characteristics of Lateritic Bauxite Deposits of India and Their Significance in Mineral Processing Pravin Bhukte*, Gopal Daware, Tejas Bhosale, Bhargavi Kulkarni and Anupam Agnihotri Jawaharlal Nehru Aluminium Research Development and Design Centre (JNARDDC), Amravati Road, Wadi, Nagpur-440 023 (MS), India

Challenges with Characterizing and Processing Goethite-Rich

2024年2月3日 XRF Analysis Traditional Bauxite Mines. The XRF data for bauxites from the traditional mines are in Table 4 and those for the new mining area are in Table 5.As with previous tables, samples are organized based on the XRF concentrations of P 2 O 5 in the original unsieved samples. Data for the traditionally mined ores show that the concentrations of Al 2 O

Aluminum Mineral Processing and Metallurgy: Iron

2018年11月5日 3. Iron-rich bauxite processing and metallurgy. Iron-rich bauxite ore usually contains over 40 wt% iron oxide [11, 12], huge reserves are found in Australia, Guinea, Brazil, Laos, Vietnam and China, but they have not yet

The Bauxite Industry and Its Development SpringerLink

2023年10月25日 The metal aluminium was first discovered and named by British scientist, Sir Humphrey Davy, in 1808. French chemist, Pierre Berthier while working near Les Baux in southern France in 1821, discovered soil with high quantities of aluminium oxide (or alumina) and named it bauxite after the village (Davis 1989; Gow and Lozej 1993).The material was deemed

Evaluating the Behavior of Bauxite Tailings Dewatering in

2023年9月6日 Depending on the ore quality, a washing process can be conducted with the bauxite, which basically consists of scrubbing the ore and screening in order to increase the available alumina grade, i.e., the alumina extractable using the Bayer Process, and reduce the impurity content. Tailings are usually disposed of in a tailings dam in the form of a slurry, which

Bauxite: Geology, Mineralogy, Resources, Reserves and Beneficiation

Bauxite deposit: geometrically defined space, geological unit composed of the bauxite body and its associated formations.In practice they are the subjects of the mining operation. Duricrust—cuirassé: Iron rich (Fe 2 O 3 % attains as much as 60–80%) layer developed on the topmost level of the laterite section in 0.2–0.3 m thickness It is mostly laminar or scoriaceous

Chemical Processing of Bauxite: Alumina and Silica

In Fig. 4.1, the numbers 150-200-250 on the graphs of equilibrium relate to caustic soda concentrations in Na 2 CO 3.A/C denotes aluminate ion concentration as Al 2 O 3 (A)/caustic soda concentration as Na 2 CO 3 (C). A typical Bayer process cycle with low temperature digestion is also shown. Virtually each bauxite contains more or less amount of clay minerals,

Age d biochar alters nitrogen pathways in bauxite-processing

37 Bauxite-processing residue sand, aged acidic biochar, Nitrogen loss, rehabilitation 38 39 1. Introduction 40 The increasing demand for alumina from fast-growing developing countries has driven the increased 41 production of bauxite in recent years. Australia is the largest producer of bauxite in the world, with

Bauxite Processing Residue: A Critical Review of Its Formation ...

2011年2月2日 Abstract. Bauxite is processed in alumina refineries by the Bayer process in which Al-containing minerals are dissolved in hot NaOH. The insoluble solids (bauxite processing residue mud and sand) are washed, sometimes partially neutralized (using CO 2 or seawater treatment), and deposited in impoundments surrounding the refinery using either wet (15–30%

Aluminum processing - Ores, Refining, Alloying Britannica

Aluminum processing - Ores, Refining, Alloying: Aluminum is the third most abundant element on Earth’s surface. Only oxygen and silicon are more common. Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum. Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic form.

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت